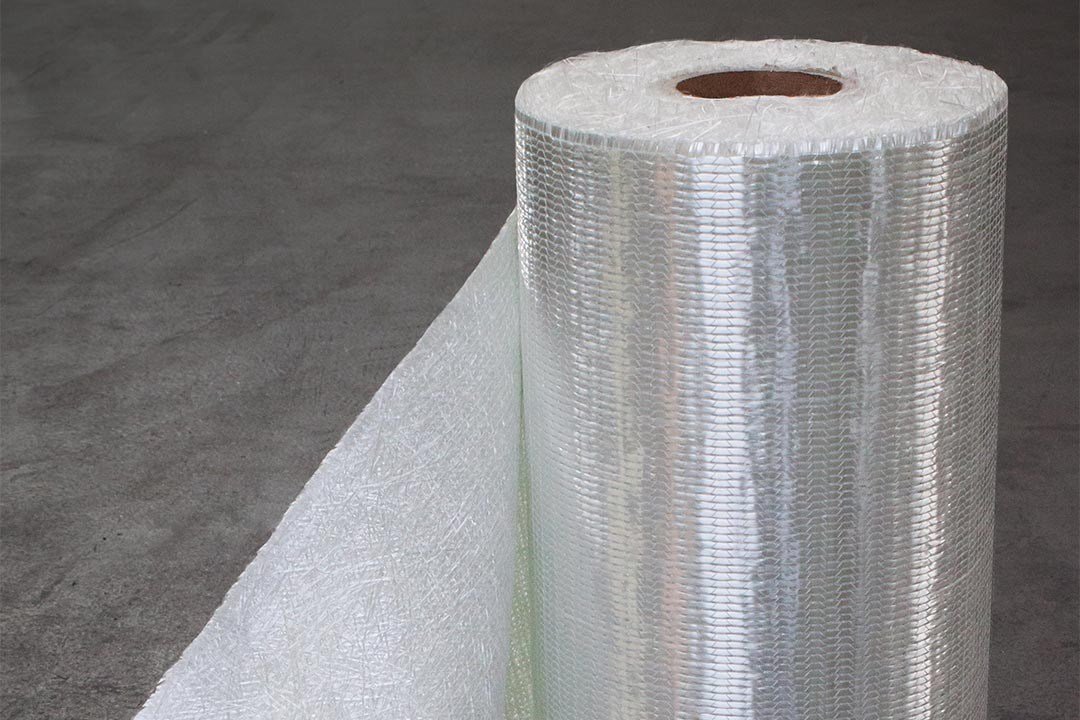

Glass fibre mats for the

RS MaxPatch® System

Trenchless repair method with DIBt approval

Alongside the pipe lining rehabilitation systems, RS MaxPatch® is available for fast, trenchless and punctual repairs.

RS MaxPatch® is a proven, on-site curing short liner system for renewing short sections in pressureless pipes from DN 100 to DN 800.

The corrosion-resistant glass fibre composite system is ideal for repairing and sealing pipe damage.

Application examples:

- small cracks

- leaks

- branch leakages

- corrosion damages

- root penetration

The high-strength resin/glass fibre matrix offers enormous structural strength with an extremely slim profile. This helps not to obstruct the pipe flow but to even improve it.

Curing even under water

RS MaxPatch® cures at ambient temperatures with virtually no shrinkage and even under water. The resin ensures the best possible sealing of the defective pipe and eliminates the need for a preliner and heating system.

The RS MaxPatch® has extensive suitability tests and is approved by the German Institute for Building Technology (DIBt).

Do You Have Questions?

Would you like to know more, do you have a specific question about the RS MaxPatch® system or would you like to place an order? We will be happy to help you directly.

Markus Dinklage

Sales Manager DE

Jürgen Haug

Sales Manager AT

Christoph Turk

Sales / Technical Management

Franziska Rosser

Authorised Signatory

Technical specifications

Diameter range

• DN 100 up to DN 800

Technical specifications

• RS MaxPatch Advantex ECR glass

• Glass mat rolls available in 330 mm/ 415 mm/ 510 mm and 1300 mm sizes

• Weights: 1086 g/m² or 1387 g/m²

Quality control

• RAL-Quality mark S27.10 (Water) & S27.2 (Steam)

• DIBt – Approval Z-42.3 – 389

• DIBt – Approval Z-42.3 – 454

• DIBt – Approval Z-42.3 – 487 [inside buildings]

Product information as pdf download

Devices

Consumables

Extension variations

Application

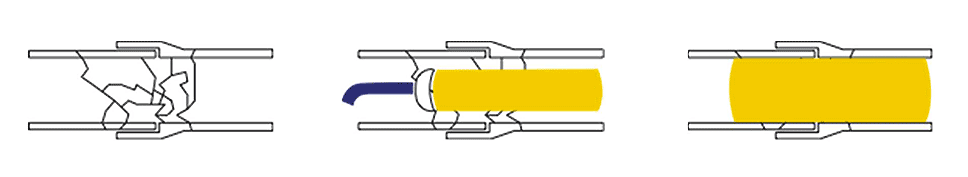

To protect the packer, a release agent is first applied to the packer. The packer is then evenly wrapped with a protective film and fixed in place.

The size of the glass fibre mat is calculated. It depends on the damaged area and a prescribed overlap.

The different resin components are mixed according to the process description. The resin is then distributed several times onto the glass fibre mat.

The impregnated glass fibre mat is wound onto the prepared packer several times, fixed and then inserted into the pipe.

The packer is positioned at the point of the damage. The curing takes place under the given pressure within the calculated curing time.