Our all-rounder in the extension variation <7.5t

The RS MaxLiner® system has been a well-established system for the renovation and renovation of domestic and underground pipelines for many years. Whether house connection or in-house renovation: The strength of the system is that it is suitable for various applications and covers a wide range of nominal diameters (DN 70 to DN 400). We use specially developed epoxy resins to help you stay flexible in terms of temperature resistance, handling and curing. Typical applications of the RS MaxLiners® include

- House connection lines

- Lines inside buildings

- Drainpipes

- Pipes in in industrial and commercial enterprises

The RS MaxLiner® is characterized by its variety of materials and technology, which makes it possible to select a tailor-made solution for every application.

The advantages are obvious:

- Bend mobility

- Rehabilitation of up to four dimensional changes

- Renovations with an open end

- Renovations with difficult accessibility

For contractors:

We will equip you!

We offer you the complete RS MaxLiner® system for the rehabilitation of domestic and underground lines in a fully equipped vehicle, including:

MaxPox®: Effective protection against corrosion and root penetration

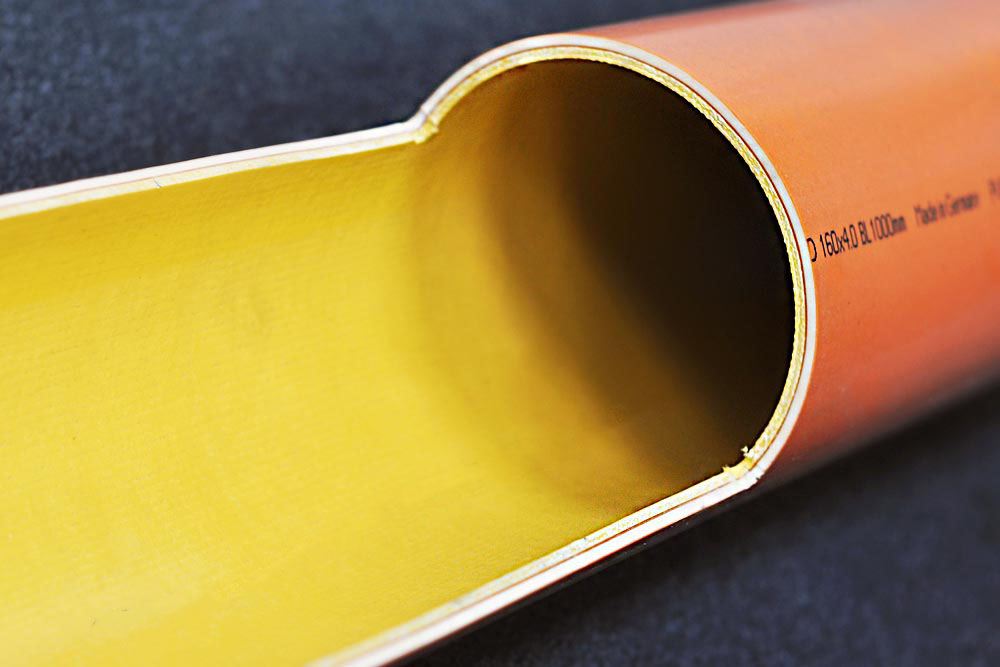

Since the MaxPox® epoxy resin system and the liner on the inner pipe wall form a new pipe, there is an airtight, seamless connection. In this way, neither moisture nor water can penetrate – Concrete corrosion is stopped. Thanks to the MaxPox® epoxy resin, the pipe rehabilitated with the RS MaxLiner® system also remains free from root penetration. This was demonstrated by the Institute of Plant Biology Basel in laboratory and field trials.

Inversion unit RS LinerGun®

The heart of the RS MaxLiner® system is the RS LinerGun® inversion unit, a lightweight inversion unit that can be used flexibly in the rehabilitation of pipes with inversion technology. The device is popular because of its easy handling.

The RS LinerGun® is suitable for both open and closed refurbishments.

Mixing plants

When mixing the resin, you have the choice between manual mixing, the RS CMU® mobile mixing plant or our high-end product, the RS CCM® mixing plant. It is a fully automatic dosing and mixing system that allows the air-free mixing of the resin components while optimizing the processing time.

Do You Have Questions?

Would you like to know more, do you have a specific question about the RS MaxLiner® system or would you like to place an order? We will be happy to help you directly.

Markus Dinklage

Sales Manager DE

Jürgen Haug

Sales Manager AT

Christoph Turk

Sales / Technical Management

Franziska Rosser

Authorised Signatory

Technical specifications

Possible applications of the RS MaxLiner

• Domestic and underground pipes of all kinds from the basement to the sewage system

• Pipes are renovated vertically from the roof to the basement

• Drainage pipes for garage, garden and forecourt

• Lengths of up to 100 m with bends up to 90 ° possible

• All types of host pipe materials

• Selective renovation of connectors and holes

• Installation through existing channels and openings

Diameter range

• DN 50 mm to DN 400 mm (2″ to 16″)

Technical specifications

• Resin mixing plant output: 18 kg / min

• Vacuum pump suction capacity: 16 m³ / h

• Tanks capacity: resin 260L, hardener 122L

• Generator power: 5kW

Examples for the individual configuration of the RS Maxliner®

• Mixing unit RS CCM® incl. PLC control via Siemens Touch Panel

• resin mixing plant with PLC system

• External vacuum pump V-VTN16 External vacuum pump V-VTN 16 (pumping speed: 16 m³ / h)

• Standard mixing head to CCM

• Air conditioning system for resin and hardener available

• Tanks conforming to Machinery Directive – 260 l resin, 122 l hardener

• External filling device for tank system

• One progressive cavity pump each for epoxy resin / hardener

• Incl. RS calibration roller table DN 300, electric with drum motors and built-in base including power generator

Other equipment for the RS Maxliner®

• Mobile dosing and mixing unit

• Controllable vacuum pump

• Calibration roll or Calibration roll table

• RS LinerGun® inversion unit or RS LinerCannon® inversion drum

• Mobile heating unit such as RS HotBox® or RS SteamUnit 150 Mobile Steam Generator

• Milling robot RS MicroCutter®

Quality control

• RAL-Quality mark S27.10 (Water) & S27.2 (Steam)

• DIBt – Approval Z-42.3 – 389

• DIBt – Approval Z-42.3 – 454

• DIBt – Approval Z-42.3 – 487 [inside buildings]

Product information as pdf download

Devices

Consumables

Extension variations

Installation

Depending on the pipe layout, the RS MaxLiner® is installed from the drain, from the basement opening or from roof drains. Special liner types and epoxy resins and hardeners are available for the various piping systems.

The liner is cut to the required length and the two components (MaxPox® resin and hardener) are mixed.

With the RS LinerGun® (inversion device) the soaked liner is installed with compressed air in the damaged pipe. The liner is kept under pressure until the epoxy mixture has cured. Hot water or steam can accelerate the cure.

The epoxy mixture is filled into the liner and evenly distributed in the liner with the calibration roller.

Inlets closed by the liner can be opened with the milling robot RS Cutter.