Tailor-made renovation

The RS MaxLiner® system offers contractors a reliable and professional basis for modern refurbishments. The system is available in various versions depending on requirements such as dimensional changes, curve mobility and wall thicknesses. They bring their advantages to bear optimally for the respective applications and requirements.

RS MaxLiner® Fix

- Seamless flexible polyester fibre hose with PU coating

- Bends up to 90°, dimension change possible

- A calibration hose must be used for dimension changes and bends.

- Cold curing and hot curing with water

- Available from DN 70 to DN 200

Raw thickness: 4.0 / 5.0

Final thickness: 3.0

Bends: up to 90°

DN change: 1

Max. Expansion: 30%

Undersize: 10%

Installation pressure: 0.2 – 0.3 bar

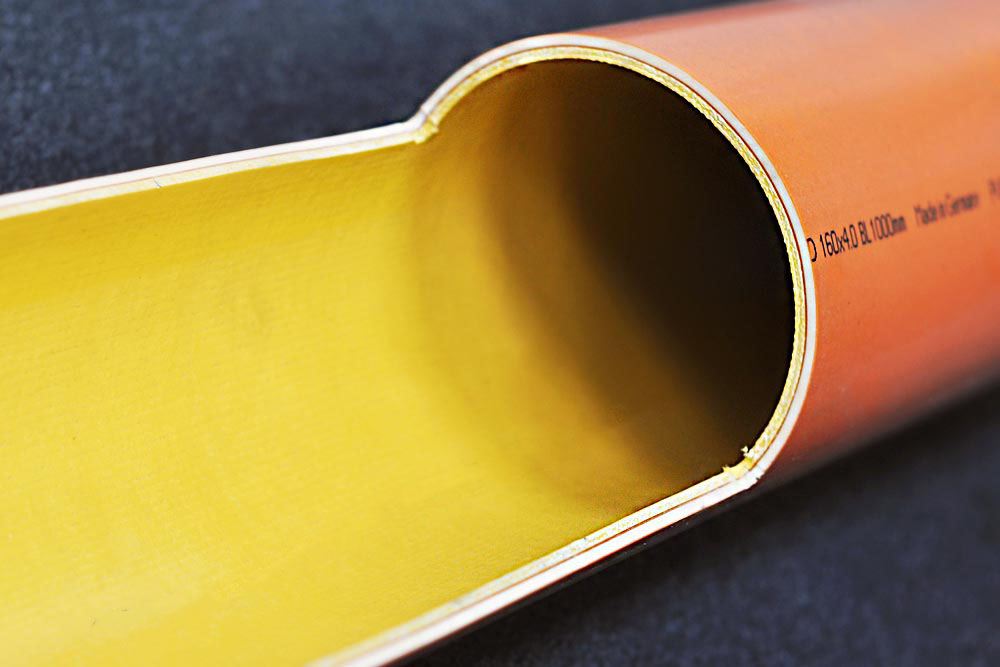

RS MaxLiner® Flex

- Flexible needle felt liner with PU coating

- bends up to 45°

- Wall thickness stable needle felt material (ensures 3 mm minimum wall thickness)

- Cold curing and hot curing with water or steam

- Available from DN 70 to DN 400

Raw thickness: 4.0 / 6.0

Final thickness: 3.0 / 5.0

Bends: up to 45°

DN change: –

Max. Expansion: 10%

Undersize: 7.5%

Installation pressure: 0.3 – 0.4 bar

RS MaxLiner® Flex S

- Highly flexible needle felt liner with PU coating

- Can be bent up to 90°, dimension change possible

- Installations with closed end can also be implemented for dimension changes

- Wall thickness stable needle felt material (ensures 3 mm minimum wall thickness)

- Cold curing and hot curing with water or steam

- Available from DN 50 to DN 400

Raw thickness: 6.0

Final thickness: 4.5

Bends: up to 90°

DN change: 1

Max. Expansion: 35%

Undersize: 10%

Installation pressure: 0.3 – 0.4 bar

RS MaxLiner® Flex 4D

- Extremely flexible needle felt liner with PU coating

- bends up to 90°, up to 4 dimension changes possible (DN 150-DN 250)

- Installations with closed end can also be implemented for dimension changes

- Wall thickness stable needle felt material (ensures 3 mm minimum wall thickness)

- Only hot curing with water or steam

- Available from DN 50 to DN 400

Raw thickness: 5.5

Final thickness: 4.5

Bends: up to 90°

DN change: max. 4

(DN150-DN250, DN100-DN150)

Max. Expansion: 67%

Undersize: 10%

Installation pressure: 0.3 – 0.5 bar

RS MaxLiner® Superflex

- Highly flexible needle felt liner with PU coating

- bends up to 90°, dimension change possible

- Installations with closed end can also be implemented for dimension changes

- Wall thickness stable needle felt material (ensures 3 mm minimum wall thickness)

- Cold curing and hot curing with water or steam

- Available from DN 70 to DN 400

Raw thickness: 4.5

Final thickness: 3.0 / 4.5 / 6.0

Bends: up to 45°

DN change: -1

Max. Expansion: 35%

Undersize: 10%

Installation pressure: 0.5 bar

Do You Have Questions?

Would you like to know more, do you have a specific question about the RS MaxLiner® carrier material/pipe liners or would you like to place an order? We will be happy to help you directly.

Markus Dinklage

Sales Manager DE

Jürgen Haug

Sales Manager AT

Christoph Turk

Sales / Technical Management

Franziska Rosser

Authorised Signatory

Technical specifications

Possible applications of the RS pipe liners

• Domestic and underground pipes of all kinds from the basement to the sewage system

• Pipes are renovated vertically from the roof to the basement

• Drainage pipes for garage, garden and forecourt

• Lengths of up to 100 m with bends up to 90 ° possible

• All types of host pipe materials

• Selective renovation of connectors and holes

• Installation through existing channels and openings

Other equipment for the RS Maxliner®

• Mobile dosing and mixing unit

• Controllable vacuum pump

• Calibration roll or Calibration roll table

• RS LinerGun® inversion unit or RS LinerCannon® inversion drum

• Mobile heating unit such as RS HotBox® or Steam Unit

• Milling robot RS-Cutter®

Quality control

• RAL-Quality mark S27.10 (Water) & S27.2 (Steam)

• DIBt – Approval Z-42.3 – 389

• DIBt – Approval Z-42.3 – 454

• DIBt – Approval Z-42.3 – 487 [inside buildings]