Production record – RS Technik AG supplies over 1 km of impregnated RS PolyLiner DN 1400

Production record in Bergkamen – RS Technik AG delivers over one kilometer of impregnated RS PolyLiner DN 1400 / 30 mm.

[apmvp player_id=”1″ playlist_id=”1″]

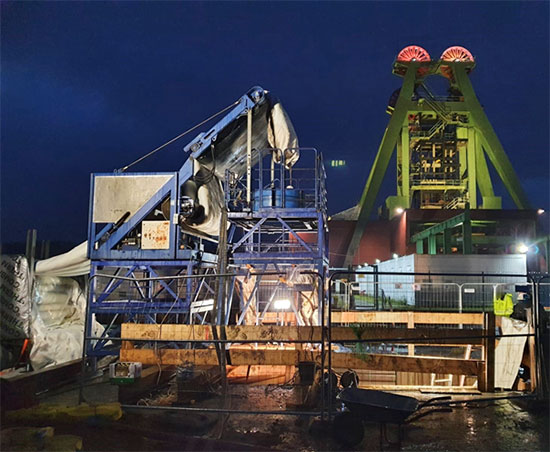

For the rehabilitation project “Haus Aden” in Bergkamen / Germany, RS Technik AG took on the challenge of impregnating more than 1,000 m RS PolyLiner DN 1400 and providing it to the customer Diringer & Scheidel Rohrsanierung GmbH & Co.KG on time and without any problems. For this purpose, a total of six pipe liners were impregnated with the polyester resin system RS MaxPol and delivered on schedule to the installation site on the premises of the future “Wasserstadt Aden”. The individual lengths of the liners were up to 200 m with a wall thickness of 30 mm.

Thanks to the experienced team of RS Technik AG and the exact planning in terms of impregnation, handling and logistics, all liners could be delivered to the construction site “just in time”.

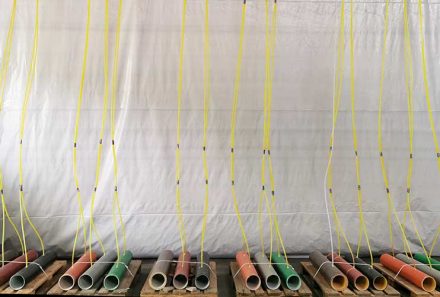

Preparation: Vacuum support for air-free filling of the liner.

Logistics: Movement and positioning of the liner during impregnation with forklifts and conveyors.

To meet the strict schedule, impregnation and loading was carried out in a three-shift system over several days. Continuous monitoring and testing ensured the quality of the product. This included, among other things, the constant cooling of the liner, which was realized with several tons of flake ice.

Cooling:The liners are optimally cooled with several tons of flake ice.

Loading: On a special low-loader, the liner is pulled up with a winch layer by layer and then secured.

State of delivery: The liner, surrounded by ice and safely stowed under thermal hoods, is ready for transport to the construction site.

This also contributed to the fact that the liner transport, which was carried out by low-loader, had a total weight of up to 85 tons. The body was specially insulated to keep the liners cool.

The entire process, from liner impregnation to loading and precise delivery to the construction site, was always carried out in close coordination with the construction management of Diringer & Scheidel Rohrsanierung.

After inversion of the impregnated liners by means of water pressure, they were hardened by heating the up to 315 m³ water filling. Precise coordination of four heating systems with a combined output of several thousand kW and seamless monitoring of the temperature conditions in the outer laminate ensured reliable curing and thus the quality of the end product.

Thanks to the careful planning and smooth cooperation between RS Technik AG and Diringer & Scheidel Rohrsanierung, the rehabilitation project was successfully completed and a contribution was made to building the infrastructure for the future water city of Aden.