RS Liner and the RS Epoxy Resin System from RS Technik AG are used all over the world in the field of sewer rehabilitation. When we then find feedback from companies or, as in this case, a post on social media, we are very pleased.

The sewer rehabilitation company Risanamento Fognature S.P.A in Italy reports on LinkedIn about the use of RS-Technik products in their application in Milan.

As part of the #PianoQuartieri of the Municipality of Milan, #MM is carrying out a rehabilitation and renovation of the sewer system in District 1, between Gesù, Borgospesso and Santo Spirito streets.

Trenchless sewer rehabilitation: the intervention is carried out with NO-DIG technology, which avoids outdoor excavations thanks to the use of tankers and mobile site excavations, reducing execution times, environmental impact and surface noise.

LinkedIn-Post #1

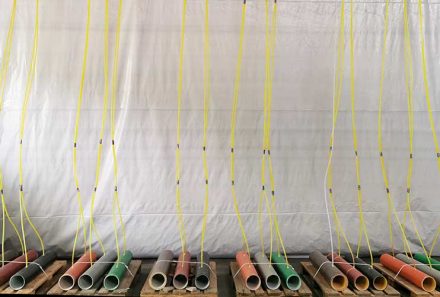

FINAL ASPECT OF A CIPP LINER DN 500/6 mm – N.3

In my opinion, this is how a UNI EN ISO 11295-11296 CIPP glass fiber liner + epoxy resin should look like after curing with the water column technique (to contrast groundwater infiltration into the pipeline)!

The glass fiber liner is filled with epoxy resin from RS Technik AG, combined with a fully PLC-controlled mixing unit on an RF truck.

(from our RF construction site in Morimondo (MI) for Gruppo CAP – DLL Ing. Enrico Polledri) #uvliner #piperelining #relining #cipp

LinkedIn-Post #2

(from our RF construction site in Milano (MI) via Gesù, S. Spirito e Borgospesso for MM Spa).

DISTRICT PLAN: RENOVATION OF THE SEWERAGE SYSTEM IN VIA GESÙ

RF – Fashion Relining between Via Montenapoleone and Via della Spiga to rehabilitate almost 750 m of DN 500/600 with minimum environmental impact and nuisance to citizens. Thanks to the staff of RF Spa, to the staff of MM Spa of DLL Ing Ferrante and to the local police.