First DIBt approval according to updated specifications for RS PolyLiner

On May 02, 2023, the in-situ curing Schauchliner RS PolyLiner received an updated General Building Authority Approval/General Design Approval (abZ/aB) from the German Institute for Building Technology (DIBt). In this, new specifications of the expert committee and the approval and licensing body could be applied in a DIBt approval for the first time.

Conversion to composite wall thickness

Requirements from DIN EN ISO 11296-4 were implemented and changed from composite wall thickness to composite wall thickness. The laminate is tested plus any wear and pure resin layers and is evaluated in its entire wall structure. A calculated deduction of individual layers of the wall structure is thus prohibited. This evaluation had also been applied to the RS PolyLiner before, since the homogeneous wall structure of needle felt and ISO-NPG polyester resin system does not require any additional wear and pure resin layers and fulfills its service life expectancy in operation. This allows clear assignment of the results on site to the target values from the type and conformity test.

Implementation residual styrene content < 2 %

Another innovation in the abZ/aB is the explicit specification of a residual styrene content of less than 2 % in the laminate. The limit value of 4 % residual styrene content in the laminate, which was still applicable in DWA leaflet 144-3: 2012, is too high and, in addition to possible effects on the service life of the systems, can also become environmentally relevant. The thermosetting pipe liner processes are characterized by reliable through-curing over the entire liner length, the entire liner circumference and, above all, right into the outer laminate layers. In practice, significantly lower residual styrene contents of less than 1 % are thus achieved here. A higher limit value is not required from a process engineering point of view and is not advisable in view of the environmental and sustainability aspects.

Determination of SDR maximum value of 135

Regardless of the result of the stability verification, DIBt requires that the SDR value (Standard Dimension Ratio = DN/wall thickness) of the design wall thickness of 135 is not exceeded. This is to maintain a defined minimum wall thickness of the pipe liner. A maximum SDR has already been demanded in the past by some network operators and engineering companies in order to avoid “sewer wallpaper”. With RS PolyLiner, the SDR is always complied with.

One resin system – one type approval

RS PolyLiner has always relied on the high-quality ISO NPG polyester resin system MaxPol and has also clearly defined this in the building authority approval. In this system specification, the type tests were carried out and prove the safe operating and usage conditions over a minimum service life of 50 years. The use of other resin types and groups requires the performance of the extensive type testing and a system approval to ensure the functional and service life.

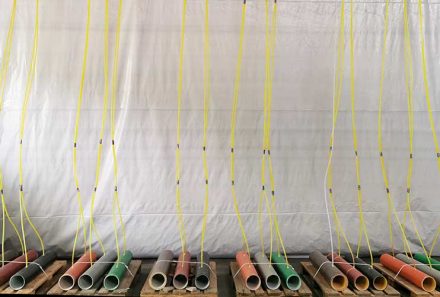

Cradle of pipe lining technology

Incidentally, the RS PolyLiner corresponds to the cradle of pipe lining in terms of its structure and curing technology. For example, the first ever pipe liner was inverted into a defective pipeline in England about 50 years ago and cured with hot water to form a new pipe. At that time, too, the pipe was made of polyester needle felt and impregnated with a polyester resin system. Laminate samples from the first installed hose liners in England and Germany still show excellent characteristic values today and testify to the high life expectancy of this material, installation and curing combination.

By adapting the DIBt approval to current specifications and requirements, RS Technik AG is implementing its motto “Focus on sustainable systems”. Because only with high-quality and defined raw materials, safe curing technology and correct evaluation, long-lasting and sustainable liner laminates are created.

This article was published in B_I MEDIEN: https://bi-medien.de/fachzeitschriften/umweltbau/kanalsanierung/rs-polyliner-erste-dibt-zulassung-nach-aktualisierten-vorgaben-u16150