RS MaxPox® Epoxy resin systems for RS MaxLiner®

Epoxy resin systems for highest demands

RS Technik relies on a solvent-free 2-component epoxy resin for the RS MaxPox® renovation system. It has excellent adhesion properties on conventional sewage pipe materials, even on wet surfaces.

Application under construction site conditions is simple and reliable.

For standard applications, the two-component epoxy resin systems MaxPox® are part of a DIBt approval.

MaxPox® Eco Epoxidharz

The MaxPox® Eco epoxy resin system is an SVHC-free two-component epoxy resin. The resin system has a modular design in pot life of 20min, 40min, 70min and 120min. It has a reduced flow behavior with less excess resin and a reliable end wall thickness.

ENVIRONMENTALLY FRIENDLY • POLLUTANT-FREE

FUTURE-PROOF

MaxPox® 15M epoxy resin

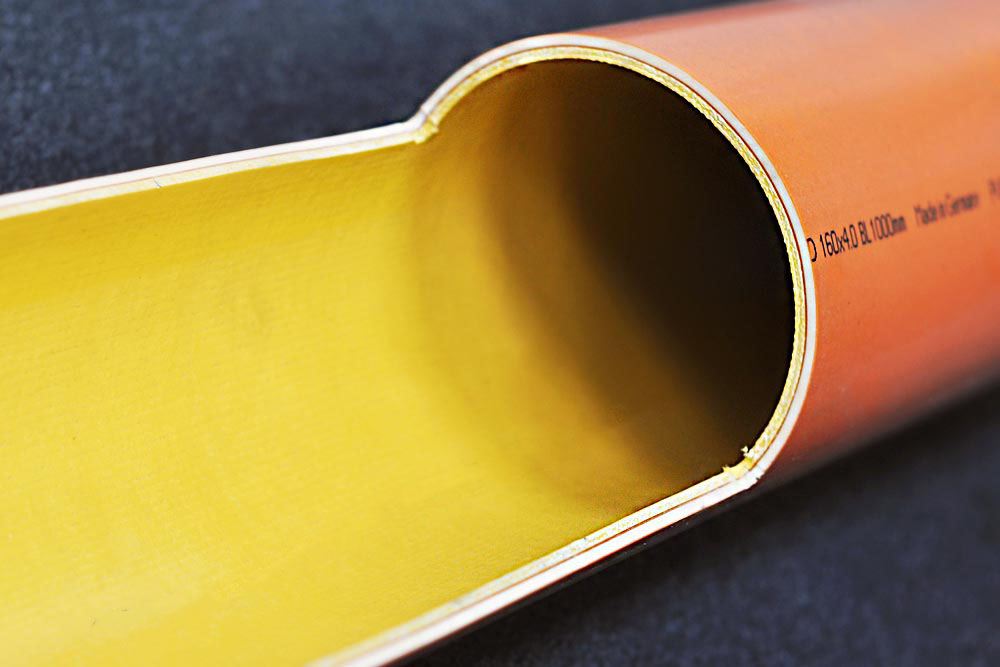

The epoxy resin system made of MaxPox® 15 M (resin, 100 parts by weight) and MaxPox® 20 (hardener, 25 parts by weight) was specially developed for the rehabilitation of sewage pipes and lines in the house connection area and is therefore an integral part of the RS MaxLiner® and RS MaxLiner® S rehabilitation systems.

MaxPox® 20 Hardener

- Hardener component for processing with the resin MaxPox 15M

- Working time at 20°C approx. 20 to 30 minutes

- Hot curing with water or steam

MaxPox® 40 Hardener

- Hardener component for processing with the resin MaxPox 15M

- Working time at 20°C approx. 40 min.

- Suitable for cold curing, hot curing with water or steam

MaxPox® 70 Hardener

- Hardener component for processing with the resin MaxPox 15M

- Working time at 20°C approx. 70 min.

- Suitable for cold curing, hot curing with water or steam

MaxPox® 120 Hardener

- Hardener component for processing with the resin MaxPox 15M

- Working time at 20°C approx. 120 min.

- Hot curing with water or steam

MaxPox® Fill A (resin) | Fill B 30, 60, 90 (hardener)

- Prefilled and yellow colored two-component epoxy resin system with improved flow behavior

- High viscosity for good hold in the support material

- Processing time at 20°C approx. 30/60/90 min (depending on hardener components)

-

Hot and cold curing possible

- B 30 suitable for cold curing, B 60 and B 90 for hot curing only

Developed especially for the RS MaxLiner® Fix, as a filled, highly viscous (viscous) resin adheres better to the carrier material.

MaxPox® Thermo

MaxPox® Thermo is a solvent-free, red pigmented, two-component epoxy resin system specially designed for the rehabilitation of industrial wastewater pipes. It is characterized by a very long processing time as well as a very high thermal and chemical resistance.

- High temperature resistance up to 90°C

- Only suitable for hot curing with water or steam, at min. 60°C

- Long processing time at 20 °C approx. 16 h

Advantages of the epoxy resin system for our RS MaxLiner®

Do You Have Questions?

Would you like to know more, do you have a specific question about the two-component epoxy resin system or would you like to place an order? We will be happy to help you directly.

Markus Dinklage

Sales Manager DE

Jürgen Haug

Sales Manager AT

Christoph Turk

Branch Manager