Sewer rehabilitation for main collectors: flexibility beats the same old scheme

Zollikon / Bergkamen. Flexibility is required when four different nominal sizes are required for a sewer rehabilitation project. DN 250, DN 300, DN 350, DN 400 – the Munich branch of DIRINGER & SCHEIDEL ROHRSANIERUNG GMBH & Co. KG recently rehabilitated more than one kilometre of sewer in a municipality in the Allgäu region. The RS CityLiner® from the Swiss supplier RS Technik AG, which is based on high-quality epoxy resin, came into use. Due to its expansion properties, it easily compensates for dimensional fluctuations even within the liner production sizes.

“The flexibility and good elongation properties of a liner are of great importance in the trenchless rehabilitation of difficult old pipe shapes”, emphasizes engineer Christian Schwab, head of Diringer & Scheidel Rohrsanierung NL Munich. “In the case of manifolds, we often do not have to deal with pipelines in standard sizes, but with an extremely inhomogeneous environment, which nevertheless requires a correctly adapted liner over the entire pipe”. The planning services required for this are based on a precise damage analysis and measurement of the old pipe. From the point of view of the D&S expert, however, it is equally decisive for the success of the measure that the method and liner were not selected according to a fixed scheme, but tailor-made. “In addition to an expert adhesion of the liner, material and expansion properties make a significant contribution to the sustained success of the project”.

Epoxy Liner proves effectiveness in inhomogeneous old pipes

Dr. Susanne Leddig-Bahls from IQS Engineering AG also confirms that, apart from the different nominal diameters, the flexibility of the liner is often in demand:

“Clients are becoming increasingly sensitive to the fact that the reliability of the materials and processes used is important, and are also strengthening their quality monitoring processes.” This not only applies to the testing after installation of a liner, but also to a more intensive planning service in advance. “The realization that a precise measurement has a positive influence on the result is gaining ground. This is because knowledge of dimensional fluctuations in the old pipe offers the possibility of selecting the product in such a way that it can handle these fluctuations in the sewer in any case”.

In the ideal case, the liner effortlessly compensates for corrosion damage, dimensional changes, flushing damage, joints, side inlets and bends, and its characteristic values continue to meet the requirements. “This is the goal from which one does not have to deviate even with bends and dimensional fluctuations. This is where the needle felt liner impregnated with epoxy resin can show its strengths due to its elasticity, dimensional accuracy and wall thickness tolerance” according to Leddig-Bahls.

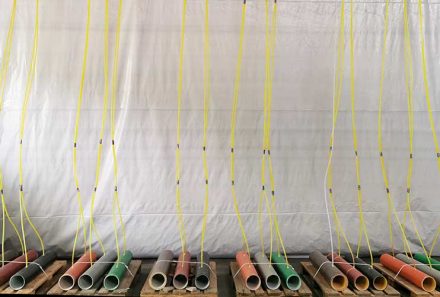

From a single cast – into the manhole

The RS CityLiner® is a needle felt hose liner, which is soaked and calibrated on site with a high-quality epoxy resin system using an automatic dosage and mixing system. The special impregnation system from RS Technik, with which Diringer & Scheidel Rohrsanierung also operates as the market leader, guarantees complete automatic documentation of the dosage, mixing and impregnation process with its complete equipment. The inversion of the liner is carried out with the aid of water pressure and curing with hot water, so that the liner can be produced from a single cast from a special vehicle. In addition, the use of pressure drums and curing with steam is possible. The glass-fibre reinforced needle felt liner CityLiner® Glass extends the system by a further carrier hose, which allows smaller wall thicknesses and is nevertheless flexible in application.

The RS CityLiner® process was successfully used to complete the renovation in the Allgäu municipality of Markt Türkheim, where a total of 31 pipe sections were lined with a 1200-metre-long pipe liner.

The municipality of Markt Türkheim had accompanied the tender by the Güteschutz Kanalbau, which confirmed the bidder’s suitability by unannounced inspections carried out by specialised engineers. The mechanical equipment and self-monitoring are also evaluated in this context. “A high-quality, flexible system and equipment are certainly important factors for the quality and durability of the rehabilitated pipeline. The combination with well-trained employees on site, who know the handling of the system by heart, provides additional security”, emphasises Jürgen Haug, Managing Director of RS Technik. In addition to vehicle equipment, refurbishment equipment and consumables, the company also offers training courses and construction site coaching for handling the systems.