Verification of the waterproof connection to the old pipe for the RS MaxLiner®

By Dr. Susanne Leddig-Bahls, IQS Engineering

The rehabilitation of house connection pipes represents a particular challenge for the pipe lining technology due to complex pipe routes and often difficult accessibility. In an extensive test with various pipe materials, the full-service system provider RS Technik AG has now proven the following: With the largely shrink-free curing epoxy resin systems, house connection liners can be installed without an annular gap and with a bond to the old pipe. The connection to various old pipe materials is possible without any leakage – provided the old pipe is thoroughly cleaned – so that no additional connection technology is required for the connection to the main sewer, the old pipe or side inlets.

Initial situation

In principle, the following maxim applies to pipe lining: it must be prevented that waste water gets between the liner and the old pipe and possibly escapes uncontrolled. This means that all liner connections must be waterproof and free of backflow. If necessary, the liner must be fixed in the bonding area. This is one of the rules that has strengthened confidence in trenchless technologies for many years.

However, in many situations, especially in the house connection area, the installation of such fixings is problematic if narrow pipe routes prevent the installation of connection adapters or liner end sleeves or similar. Despite progressing developments, the so-called “dead end” of a pipe liner in inaccessible areas is still one of the challenges.

Epoxy systems, which are introduced into the old pipe from even the smallest access points during house connection renovation with the aid of sophisticated installation techniques, can play to their strengths here due to their chemical properties. Thus they can be attached and hardened due to their special characteristic of the shrink-free nature and basically provide good adhesion to the structure of the old pipe. This indicates that a connection with epoxy systems that is free of leakage can be created, which makes the use of additional connection techniques obsolete.

An important definition of the term is inserted here. Even though we speak of adhesive systems for epoxy resins due to the advantages mentioned above and adhesive processes are defined as “material-locking joining processes”, it is not possible to ensure material adhesion at every point of the old pipe in the same way. Thus, a high adhesive tensile strength cannot be achieved in every area and on every substrate. Nevertheless, a waterproof connection free of infiltration can be achieved.

Approach

How can a waterproof link to the rehabilitated manifold be ensured and evaluated? To date, there has been no corresponding proof, which considers the challenges of house connections and in particular the difficult plastic pipe surfaces. Due to their surface properties, old plastic pipe materials can only be used to a limited extent for material-locking connections with common resin systems. A further typical problem in the house connection area is the fact that the old pipe systems have grease layers during operation, which cannot be completely removed even after high-pressure flushing, so that significant separating layers for systems can develop here.

Experimental arrangement

RS Technik AG has commissioned IQS Engineering AG to design a suitable test and to carry it out for the RS MaxLiner® method. IQS, in coordination with and accompanied by the accredited testing laboratory Siebert + Knipschild GmbH, developed a test concept and prepared a test plan which, among other things, takes into account a greasy old pipe surface and an external water pressure of up to 5 metres water column. This test was carried out for three different epoxy resin systems and two different carrier materials of the RS MaxLiner® process.

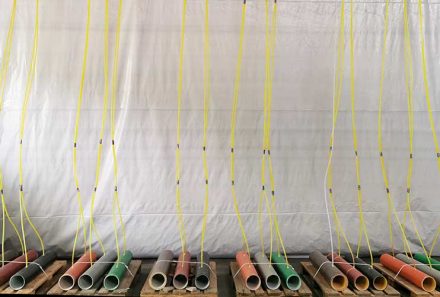

The verification was carried out on the common plastic pipe materials KG pipe (PVC), HT and KG2000 pipe (PP), PE pipe and cast iron pipe (SML). All pipes were thoroughly coated with deep-frying grease on the inside and joined together to form three test sections (Fig. 1). In addition, two 10 mm holes were drilled into each pipe. These holes were to expose the transition between pipe and liner for the test and at the same time prevent overstretching of the pipe liner in this area. After exposure to the deep-frying fat for at least 24 hours, the three test sections were cleaned in three rinsing cycles with a standard site rinsing device using high pressure water (Fig. 2) and the grease layer was thus removed to such an extent that a sufficient connection of the liner to the pipe could be created. The epoxy resin-soaked liners were then installed and cured (Fig. 3).

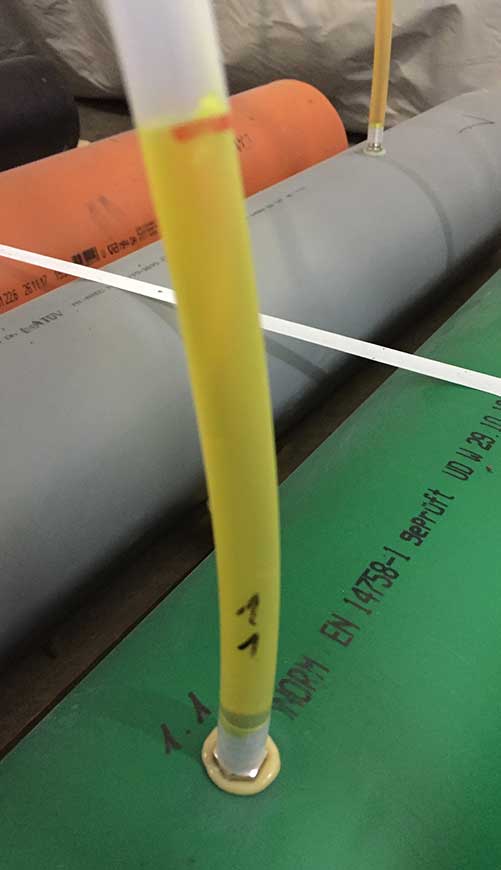

Following the liner installation, the holes were redrilled and freed of excess resin to ensure that the boundary layer between the liner and the old pipe was exposed and that no resin, dust or similar could falsify the test (Fig. 4). Hose connections and approx. 5 m long transparent hoses were attached to the boreholes and filled with water to form a buckling pressure (Fig. 5). A fluorescent test liquid was added to the test water in order to make any backflow between the liner and the old pipe as well as leaks in the liner laminate clearly visible (Fig. 6). The detection was carried out in several pressure stages (Fig. 7), which were always maintained for at least 24 hours and extensively tested and evaluated: 0.15 mWS (water column)/ 1.50 mWS / 3.00 mWS / 5.00 mWS.

Results

The evaluation of the test showed that the three RS MaxLiner® resin systems tested did not show any backlashes of up to 5 mWS external water pressure with plastic and cast pipe materials in the test. The hoses did not show any water loss and there were no ink penetrations in the liner laminate. Since 11.04.2019 (3 months), the water column of 5.0 metres has been standing on the various laminates and confirms the watertight connection of the liners to the plastic pipes (Fig. 8). The engineering office Siebert und Knipschild accompanied the test in the individual stages and presented RS Technik AG with a corresponding test certificate (Fig. 9).

Conclusion

The verification of the waterproof connection of the RS MaxLiner® epoxy resins to plastic and cast iron pipes could be achieved with this test. The goal of the remediation of the waterproof and backflow-free connection is achieved by bonding the liner to the pipe. The DIBt approval for the RS MaxLiner® already contains the information that a waterproof connection can be made without additional connection technology. In practice, this enables the liner to be connected to the cleaned old pipe without the use of a hat profile, liner end sleeves or other systems.