Sustainable pipe lining systems based on epoxy resin

RS Technik AG has been promoting trenchless pipe rehabilitation using pipe lining since 1992 and is convinced of the use of the highest quality epoxy resins for the sustainable maintenance of underground infrastructure.

RS Technik AG was founded in Switzerland in 1992 (at that time still as RRS GmbH) and has been developing and marketing rehabilitation systems and materials for the rehabilitation of pipelines ever since. “Out of conviction, we have been relying on the high-quality epoxy resins, which are reliable, high-performance and durable, for 30 years now.” – says Klaus Müller, managing director and founder of RS Technik.

The use of epoxy resins is indispensable, especially in the field of house connection renovation. The flexible mixing and transparent impregnation on site, the safe curing under any ambient conditions and the excellent adhesion to the pipe materials at hand ensure a wide range of applications. In combination of the proven epoxy resin systems with particularly stretchable and flexible liner materials, up to four nominal diameter changes in the pipe run and several bends in succession can be reliably sealed. Special attention in the house connection area is paid to the possibility of inserting the liner with only one access point. These so-called open-end installations require a watertight connection of the pipe liner to the old pipe without back migration. The MaxPox epoxy resins from RS Technik AG score here with reliable adhesion and dimensional stability. The watertight connection of the pipe liner of the RS MaxLiner system has been proven by the accredited test laboratory and is part of the general building authority approval.

The use of epoxy resin-based hose methods has also proven itself in the main sewer area. “Especially in industrial applications, the high chemical resistances of epoxy resins are in demand,” says Klaus Müller. In addition, there are often old pipe materials that have fluctuating inner pipe diameters. This is already production-related or the result of years of internal corrosion and abrasion. Long-lasting hose processes have to fit closely to the old pipe and thus compensate for these fluctuations. Flexible needle felt liners are convincing with their high elongation capacity and can reliably compensate for these internal dimensional tolerances.

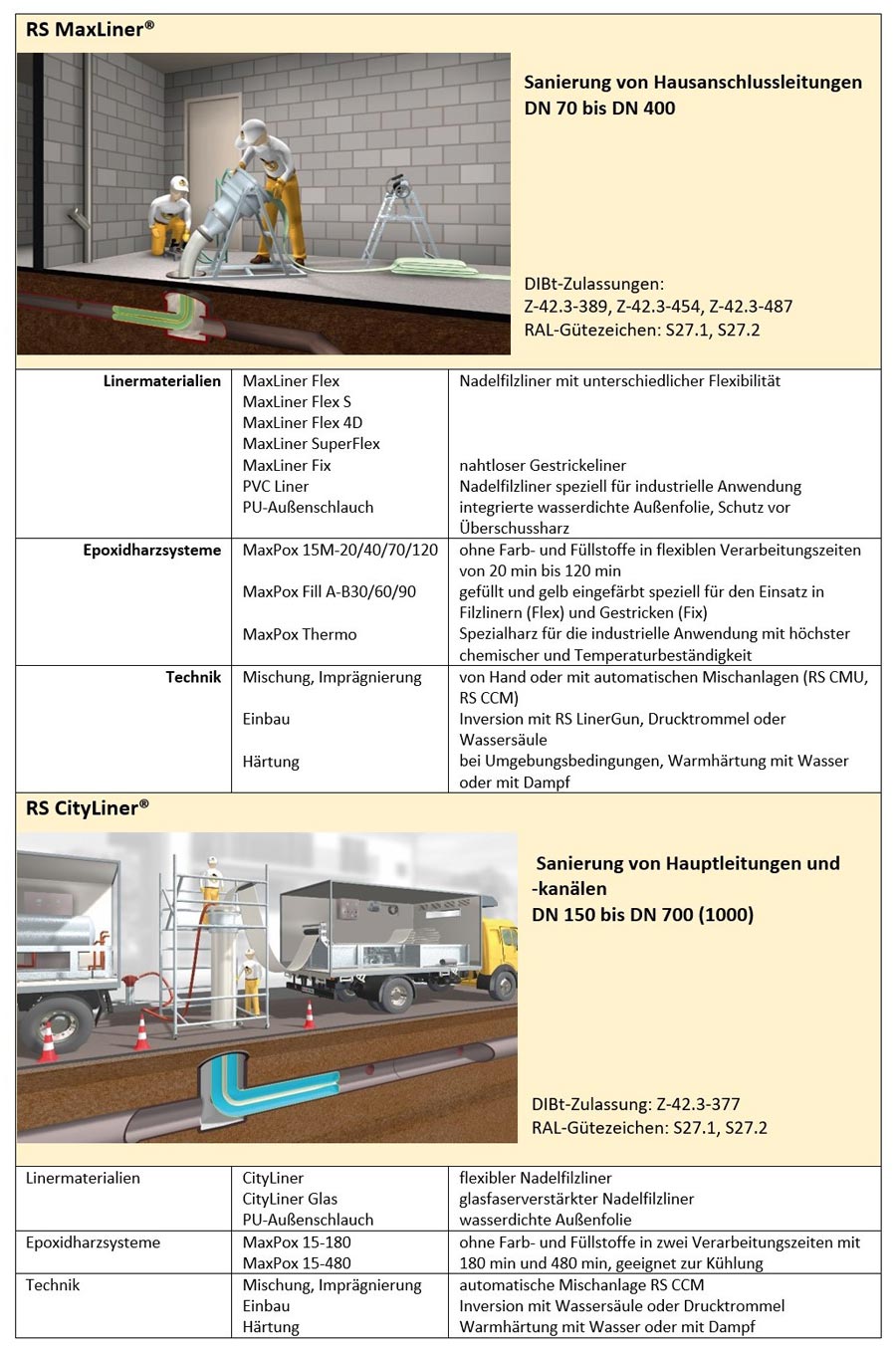

The following table provides an overview of RS Technik’s epoxy resin-based hose processes:

Table 1: RS Technik AG’s epoxy resin-based hose processes.

“Sustainable pipe rehabilitation often requires tailor-made solutions for the application at hand. For this reason, we rely on a variety of materials and techniques. In this way, an optimal selection can be made from an economic and technical point of view for each user and area of application,” explains Klaus Müller. The pipe lining systems for on-site production offer flexibility and transparency. This means that unforeseen conditions on site can be reacted to quickly and the choice of material and technology can be adapted if necessary. All processes are reproducible and fully transparent for the user and client.

We would be happy to inform you further about our experience with epoxy resin-based hose processes in practice over the past almost 30 years.