“Demands are increasing”

RS Technik, a leading provider of trenchless rehabilitation systems and equipment, can look back on a proud quarter-century success story. 25 years – a reason to celebrate and a time to set the course for the future.

“If you look at our activities over the past few years, you could say: We have achieved a lot – let´s just keep going,” said RS Technology President Klaus Müller on the occasion of the anniversary. But the dynamic company boss does not want to limit himself to this. “Anyone who knows us is aware: to just keep on doing the same – that’s not our thing. The pipeline rehabilitation market has reached a high level of distribution and professionalism, but there are always new challenges that we are fully committed to, ” says Müller, with conviction.

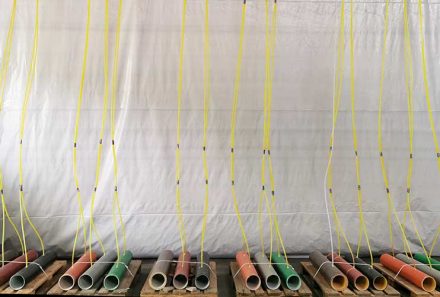

The starting position could not have been better for RS Technik AG: The RS hose line systems, which they offer to contractors, among others, in prefabricated installation vehicles, enjoy a continuing good reputation. In particular, the RS MaxLiner®, which is used in domestic and underground pipelines, is enjoying worldwide demand. In nominal widths from DN 50 to DN 400, the liner, which is impregnated with high-quality epoxy resin, adheres closely to the old pipe due to its pronounced elasticity. Even with dimensional offsets and bends, a structural load-bearing pipe-in-pipe is formed.

Focus on sustainable systems

RS Technik is focusing on the topic of progress for the next few years: environment-friendly systems, high quality standards and full-service for the implementing companies – RS Technik intends to push the growth trajectory with these priorities. “An enormously important task is not only to make repair and renovation systems safe and harmless to health, but also to ensure a sustainable and environmentally friendly material selection. „I think it pays off that we have invested heavily in development work in recent years,“ emphasizes Müller. Through cooperation with testing laboratories and development institutes, the company has obtained miscellaneous building inspectorate approvals for the systems.

Effective Co-ordination with Implementing Companies

RS Technik intends to keep in contact with implementing companies more intensively than ever before, relying on personal contact with those employees who present themselves as contact people on the new RS Technik website. “If you have a question, you want to know who you can address. We have introduced this on our new website, ” says Müller. All contact persons are provided on the page www.rstechnik.com with photo and telephone number.

RS Technik also wants to expand the area of training courses and training for users. In the Bergkamen branch, the company has set up a training centre for its German customers, where employees of contracting companies can train on site how to use the systems. “In times of a shortage of skilled workers, qualifications are more important than ever”, says Müller. The rooms are directly adjacent to the factory and warehouses – the effective co-ordination with the customer is not meant to be just proverbial.

Swiss original plant with worldwide distribution

Even though RS Technik maintains storage, administration and training facilities at a former colliery in Bergkamen, the company is and will remain a Swiss original. The company was founded in the early 1990s in Zurich under the name RRS GmbH. Two years later, following the market launch of RS CityLiners® for collection pipes in 1994, the RS MaxLiner® was installed for the first time. It is mainly used in domestic and underground lines on private land. After the change of name to RS Technik AG in 1999, worldwide distribution of liners progressed – to Asia and South America, amongst others. The BlueLine system for drinking water and pressure pipeline rehabilitation, which was developed by RS Technik in 2009, has since been outsourced to Pipe-Aqua-Tec GmbH. Incidentally, it is the only system of its kind on the market that meets the requirements of the Deutsches Institut für Bautechnik (DIBt) for alternating pressure loads.

Time and again the same question…

“Although we have been known for so long, we are asked again and again what the abbreviation RS actually stands for,” Klaus Müller says with a chuckle. The abbreviation of special investment companies? A specific abbreviation of a chemical compound used? Not even close. “The fact that RS simply stands for pipe renovation (Rohrsanierung) always comes as a surprise. So much has developed around our core business that it’s hard to believe. ”